Diesel Exhaust Removal

Articulating boom arm simple drop systems are designed for shops with overhead cranes or high ceilings that prevent users from installing other overhead systems. Pivoting articulating boom arms store tightly against the wall when not in use, and swing out over or between bays when needed.

Articulating boom arms scissor at the midpoint for maximum flexibility, making them great for a range of diesel engine repair shops.

Hose Temps: 400° / 600°

Hose Diameters: 4 to 10 inches

Length: 10, 15, and 20 feet

Tractor Exhaust Removal

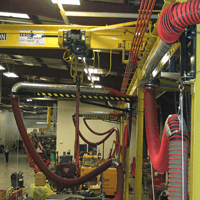

Fume-A-Vent Boom Arms for Diesel Power Equipment Co.

Application: Boom Arms Installed at Diesel Engine Repair Shop, Diesel Power Equipment Co.

Summary: Diesel Power Equipment Co. is a diesel engine repair shop with overhaul, welding, and fabrication services. The Diesel Power Equipment team provides engine horsepower, performance testing and diagnostics, hydraulic testing, fluid analysis, and rebuild cylinders, pumps, hydrostat/power-shift transmissions, and steering systems. They also service and repair engines, generators, tractors, construction, and mining equipment.

Challenge: Diesel Power Equipment Co. has an overhead Jib Crane that their technicians were working under and needed a boom arm that allowed for a longer reach of 25-feet for an extended range of motion. They wanted a safe and versatile solution to eliminate welding smoke, dust, and other dangerous air contaminants.

Solution: Our team provided articulating boom arms outfitted with cable balancers for hose storage. The articulating boom arm is excellent for shops with overhead cranes or high ceilings because they store tightly against the wall when not in use, and swing-out over or between bays when needed.