Choosing the Right Exhaust Hose

The exhaust hose is one of the most important components in a vehicle exhaust removal system because it transports harmful exhaust gases such as carbon monoxide, nitrogen oxides, and particulate matter away from breathing zones.

By effectively capturing and directing hazardous exhaust emissions away from the work area, exhaust hoses ensure a safe and healthy environment for technicians, staff, and customers.

Another key point about an exhaust hose's function is its role in improving efficiency. Exhaust hoses directly attach to a vehicles exhaust pipe or pipes with a tailpipe adapter to facilitate maximum capture of exhaust fumes at the source.

This at-source capture method minimizes the release of harmful exhaust emissions into the shop or garage, keeping air quality at an optimal level and reducing potential health and safety hazards.

When it comes to regulatory compliance, exhaust hoses are integral. Occupational health and safety regulations require workspaces, including auto maintenance and repair shops and garages, to maintain air quality standards.

The exhaust hose in a vehicle exhaust removal system, helps establish compliance with these standards by effectively capturing and redirecting harmful exhaust gases.

The versatility and durability of exhaust hoses allow them to accommodate various vehicle types and sizes, making them adaptable for any maintenance and repair facility.

Fume-A-Vent exhaust hoses are constructed to withstand high temperatures and corrosive gases, contributing to their longevity and reducing the need for frequent replacements.

When choosing an exhaust hose, it is vital to consider the specific application requirements. Using a hose that is compatible with engine performance and application demands will prevent serious risks.

An incompatible hose can lead to safety hazards, hose failure, increased maintenance and repair costs, and lost production time.

Fume-A-Vent exhaust hoses are built to accommodate a diverse range of applications. From standard passenger vehicles and diesel trucks to buses and military vehicles, our hoses offer an effective, affordable, and worry-free solution for virtually any shop, garage, or maintenance and repair facility.

Fume-A-Vent exhaust hoses can withstand temperature tolerance from 400° to 2010°, making them one of the best on the market.

In most conditions, 400° high-temp exhaust hoses are adequate for diesel applications, while 600° hoses are suitable for most gasoline applications. This is assuming that the vehicle is running idle and under minimal to no additional load.

To select the best garage exhaust hose for your application, consider these four selection factors, and never hesitate to seek expert guidance from our specialists.

EXHAUST HOSE SELECTION FACTORS

1. Identify Temperature Range

Identifying the temperature range you need to cover will determine the material of hose that is right for your vehicle exhaust system.

Rule of Thumb

400° F: Gasoline or Diesel (at idle)

600° F: Gasoline or Diesel (under load)

600° F: Dyno without direct tailpipe connection

800°-1000°+ F: Generators

1200° F: Diesel under regeneration cycles

2. Is Your Hose Compatible?

The temperature of an exhaust hose should match the engine performance level.

In addition to matching the temperature range, it's important to ensure the exhaust hose is compatible with the specific vehicle make, model, and engine type.

Factors like exhaust pipe diameter, exhaust flow rate, and back pressure requirements need to be considered to ensure the hose will work seamlessly with the vehicle's exhaust system.

Using an incompatible hose can lead to leaks, reduced exhaust capture efficiency, and even damage to the vehicle's exhaust components over time.

3. Is Your Tailpipe Adapter Compatible?

The hose diameter should match the tailpipe adapter calculation: Tailpipe + ½”

The tailpipe adapter plays a crucial role in securely connecting the exhaust hose to the vehicle's exhaust system.

Ensuring a proper fit between the hose and adapter is essential for maintaining a tight, leak-free seal.

Using the wrong size adapter can result in air leaks, poor exhaust capture, and even the hose becoming detached from the vehicle.

Some adapters are also designed with features like clamps or quick-release mechanisms to facilitate easy installation and removal.

4. Exhaust Hose Construction

The vehicle exhaust hose construction should be durable single-ply “clip-style” or dual-ply for more robust applications.

The hose material can also impact its resistance to heat, chemicals, and abrasion. Considering the specific application and operational conditions the hose will be exposed to can help determine the proper construction and material for the application.

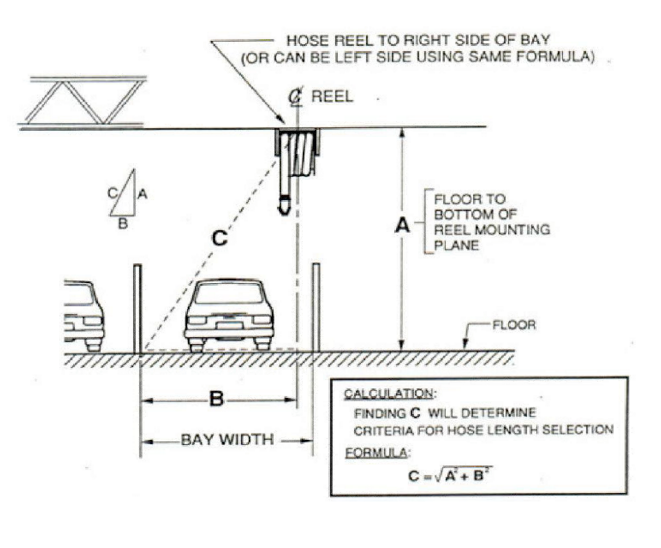

EXHAUST HOSE LENGTH CALCULATION

Selection Factors

✓ Use the height from drop to the floor

✓ Use the bay width, or distance to the furthest tailpipe

✓ Use the Pythagorean Theorem:

c = a2 + b2 — with 'c' representing the criteria for the hose length selection, 'a' representing the floor to the bottom of the reel mounting plan and 'b' reprsenting the width of the bay.

When you work with Fume-A-Vent, our specialists will provide you with system design, bill of materials, CAD drawings, specifications, quotes, and design assistance to ensure you choose the best possible exhaust hose for your specific requirements.

We understand that the exhaust hose plays a crucial role in maintaining safety, air quality, productivity, and compliance with health and safety regulations in your workplace. By partnering with us, you can rely on our expertise and support to make an informed decision that positively impacts your business, technicians, staff, and customers.

You may also like: