What Overhead Exhaust System Is Right for Your Application?

An overhead exhaust system plays a crucial role in maintaining a safe and healthy work environment in vehicle maintenance and repair shops. These systems are designed to capture and remove harmful vehicle exhaust, which contains pollutants and toxins such as carbon monoxide, particulate matter, and other hazardous pollutants.

Implementing overhead exhaust removal systems ensures that the health and well-being of technicians and employees are protected. Vehicle exhaust fumes pose serious health risks when inhaled, leading to short-term and long-term health problems, including respiratory issues, heart conditions, and cancer. Overhead exhaust systems help ensure that these fumes are captured and removed from the work area, reducing exposure and protecting workers.

In many regions, there are regulations and guidelines in place that mandate exhaust removal in facilities where vehicles run idle or higher to meet air quality and occupational safety standards. Outfitting your workspace with overhead exhaust systems helps your shop stay compliant with these requirements, avoiding potential legal issues.

Cleaner and safer working conditions can also lead to increased worker productivity. With effective exhaust removal, technicians and employees can focus on projects without worrying about overexposure risks. Businesses that prioritize worker safety and health are likely to experience fewer sick days, reducing the impact on overall operational efficiency.

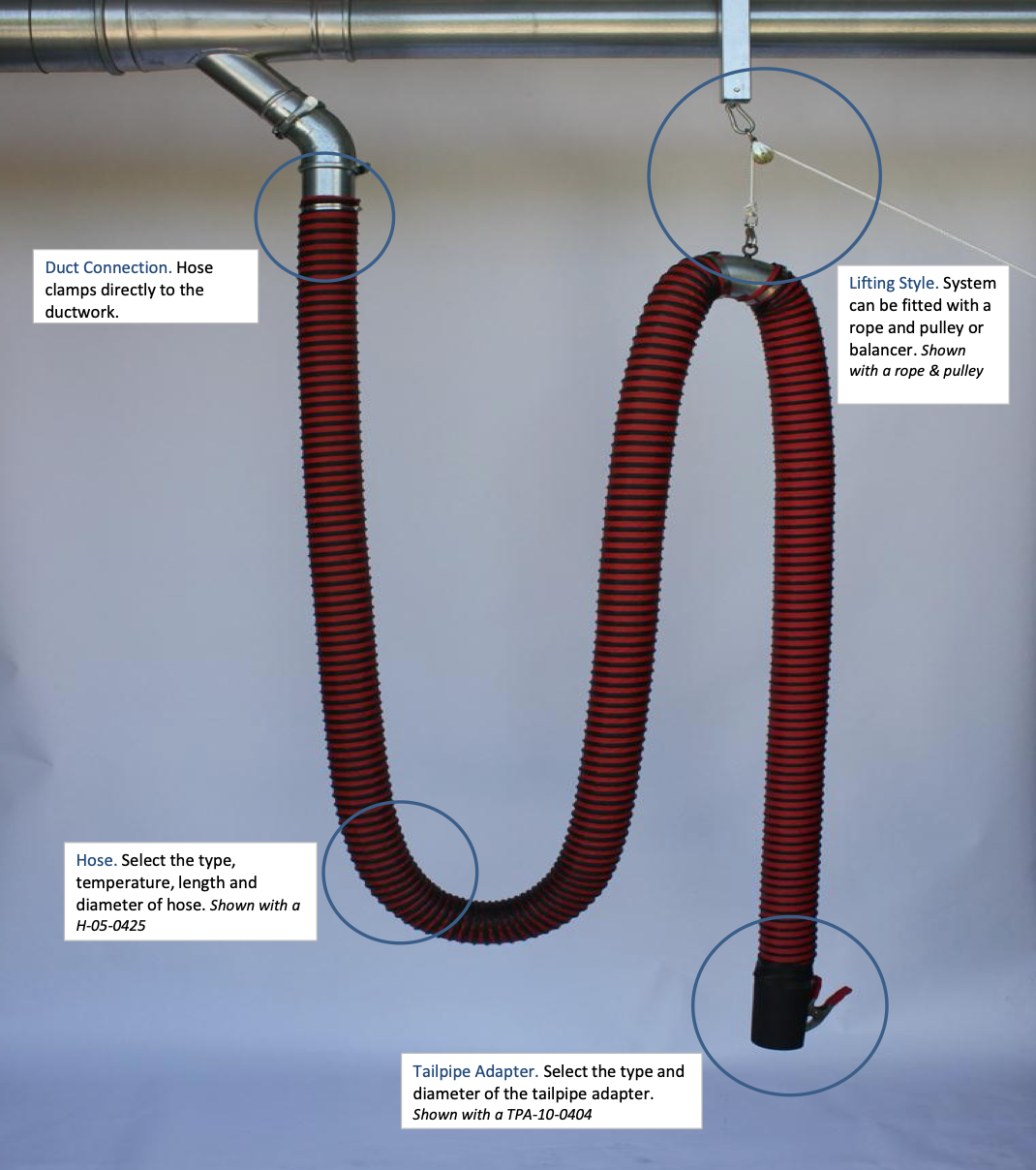

Overhead exhaust removal systems are available in rope and pulley, and spring balancer (cable balancer) configurations. The choice between a rope and pulley system and a cable balancer system depends on specific needs and preferences. While cable balancer systems are higher-end systems known for their durability and ease of adjustment with heavier hoses, rope and pulley systems offer a seamless, economical solution for lighter exhaust hoses.

Overhead Exhaust Systems Explained

Type of System

Overhead exhaust removal systems can be completely stand-alone by equipping them with a direct-mount fan or they can connect to vehicle exhaust ducting and a central fan.Exhaust Hose

The core component of the system is a flexible exhaust hose with a tailpipe nozzle or adapter designed to attach to a vehicle's exhaust pipe.

Exhaust Capture

When a vehicle is running idle or higher, its exhaust pipe or pipes are connected to the tailpipe adapter or adapters which are attached to the hose/s.

Hose Suspension

The exhaust hose is suspended from an overhead structure using a support system. This is where rope and pulley or cable balancer systems become a factor:

• Rope and Pulley System: A rope and pulley overhead system can be used to raise and lower the exhaust hose to the correct height for capturing the exhaust gases. This manual system allows the hose to be positioned as needed and then secured in place.

• Cable Balancer System: Cable balancer systems are more common for these applications because they provide precise height control and ease of adjustment. The exhaust hose is attached to a steel cable, and a cable balancer assembly ensures that the hose remains at the desired height while being easy to adjust.

Exhaust Extraction

The vehicle exhaust is captured at the source through a single or dual tailpipe adapters and transported through the hose by using an exhaust fan or blower. The fan uses its power to create negative pressure, pulling the exhaust gases away from respiratory zones and emitted outside, away from the building.

To determine which overhead exhaust removal system is the right choice for your facility, it's important to consider several factors.

By assessing the type of work that takes place in your facility you can determine if exhaust removal systems are needed to maintain a safe work environment. Typically, any workspace that involves vehicle maintenance, repair, or indoor testing where vehicle engines run idle or higher can benefit from exhaust removal.

The size and layout of your facility are huge factors in choosing exhaust removal systems and whether overhead systems are right for your space. Overhead systems are well-suited for well-defined workspaces and provide at-source exhaust capture. If your facility has multiple work bays or a dynamic layout, the flexibility of the overhead system will adapt well to your application needs.

Customization is key and our specialists can help tailor overhead exhaust removal systems to the specific requirements of your facility, including the type of exhaust hoses needed based on the vehicles and equipment you service. Overhead systems can accommodate various hose types, lengths, and diameters, and the choice should align with the temperature and size requirements specific to your application.

Lastly, evaluate your budget and compare the cost-effectiveness of overhead systems to other options, such as hose reels or boom arms. Understanding the financial aspects will enable you to make an informed decision that aligns with your facility's needs and resources.

Shop Overhead Exhaust Removal Systems

Rope & Pulley

This system package includes:

• 1 x 4" x 15' hose

• 1 x 4" lifting elbow, rope with pulley lifting system

• 4 x 4" hose clamp

• Tailpipe adapter